In the fast-paced world of dropshipping, product selection tools make it easier than ever to discover trending items, identify profitable niches, and quickly launch new products. However, many beginners face a common dilemma: just because a product looks promising in a selection tool doesn’t mean it’s safe to sell.

What if the supplier delivers poor quality? What if shipping times are unreliable? What if customers complain about defects or false advertising?

Choosing the wrong product can lead to refunds, negative reviews, damaged brand reputation, and financial losses. That’s why experienced sellers never rely solely on data from product research tools. Instead, they verify product quality through multiple dimensions before listing items in their stores.

This guide will walk you through a comprehensive, multi-layered process to validate product quality, supplier reliability, and long-term market potential—so you can sell confidently and build a sustainable dropshipping business.

Why Product Verification Matters in Dropshipping

Dropshipping removes the need to hold inventory, but it also removes direct control over product quality. Unlike traditional retail, you don’t see or handle products before customers receive them.

This creates several risks:

-

Poor manufacturing quality

-

Misleading product descriptions

-

Unreliable suppliers

-

Long or inconsistent shipping times

-

High return rates

-

Negative customer experiences

A single bad product can result in:

-

Increased refund requests

-

Payment disputes

-

Store account restrictions

-

Advertising losses

-

Damaged brand trust

Product verification protects you from these risks and helps ensure long-term profitability.

Step 1: Validate the Supplier’s Credibility

Your supplier is just as important as your product. Even a great product can fail if the supplier is unreliable.

Check Supplier History and Experience

Look for:

-

Years in business

-

Transaction volume

-

Customer ratings

-

Manufacturing capabilities

-

Certifications

-

Business licenses

Suppliers with a long track record usually have stable production processes and better quality control.

Analyze Customer Feedback

Don’t just look at the rating score—read the actual reviews.

Pay attention to:

-

Comments about durability

-

Packaging quality

-

Product accuracy vs description

-

Shipping reliability

-

After-sales service

If multiple customers report the same issue, treat it as a warning sign.

Evaluate Communication Speed

Contact the supplier and ask questions:

-

How fast do they respond?

-

Are answers detailed or generic?

-

Do they understand your needs?

Reliable suppliers communicate clearly and quickly.

Step 2: Order Samples Before Selling

Professional sellers always test products themselves.

Why Sample Testing Is Essential

Sample testing helps you verify:

-

Build quality

-

Material durability

-

Packaging standards

-

Product functionality

-

Actual appearance vs listing photos

It also lets you evaluate the full customer experience—from ordering to delivery.

What to Test in a Sample

When your sample arrives, inspect:

-

Product design and finish

-

Strength and durability

-

Safety features

-

Ease of use

-

Packaging protection

-

Accuracy of description

Document your findings carefully.

Test Real Usage Conditions

Use the product like a real customer would:

-

Test performance repeatedly

-

Try extreme conditions if relevant

-

Check for wear over time

This reveals potential issues that initial inspection may miss.

Step 3: Analyze Product Materials and Manufacturing Quality

Understanding how a product is made helps predict long-term reliability.

Evaluate Materials

Look for:

-

High-grade plastics vs cheap materials

-

Metal strength and thickness

-

Fabric quality

-

Surface finishing

-

Weight consistency

Premium materials usually result in fewer returns and better customer satisfaction.

Examine Build Precision

Signs of good manufacturing include:

-

Smooth edges

-

Tight assembly

-

Uniform color

-

No loose components

-

Consistent measurements

Poor precision often indicates weak quality control.

Step 4: Compare Multiple Suppliers

Never rely on just one supplier.

Why Comparison Matters

Different suppliers may sell similar products with different quality levels. Comparing options helps you identify the best balance of:

-

Price

-

Quality

-

Shipping speed

-

Reliability

How to Compare Effectively

Order samples from multiple suppliers and compare:

-

Material quality

-

Packaging

-

Product consistency

-

Delivery time

-

Communication experience

Choose the supplier that provides the best overall value—not just the lowest price.

Step 5: Evaluate Shipping Performance

Shipping quality directly affects customer satisfaction.

Test Delivery Speed

Measure:

-

Processing time

-

Shipping duration

-

Tracking reliability

Unpredictable delivery creates complaints and refund requests.

Inspect Packaging Protection

Poor packaging leads to damaged products.

Look for:

-

Protective materials

-

Secure sealing

-

Damage resistance

-

Professional presentation

Packaging quality reflects the supplier’s attention to detail.

Step 6: Research Market Feedback Across Platforms

Customer feedback from multiple sources reveals real product performance.

Check Online Reviews

Search for the product across:

-

E-commerce platforms

-

Forums

-

Social media discussions

-

Video reviews

Look for consistent complaints or praise.

Identify Common Issues

Recurring problems might include:

-

Battery failure

-

Fragile parts

-

Incorrect sizing

-

Poor instructions

-

Low durability

Frequent issues suggest quality risks.

Step 7: Test Return and Refund Processes

A reliable supplier supports your business even when problems occur.

Ask About Return Policies

Verify:

-

Replacement process

-

Refund conditions

-

Defect handling

-

Warranty options

Clear policies reduce risk.

Simulate After-Sales Communication

Send support questions and evaluate:

-

Response speed

-

Professionalism

-

Problem-solving ability

Good after-sales service protects your reputation.

Step 8: Verify Product Compliance and Safety Standards

Certain products must meet safety or regulatory requirements.

Check Certifications

Depending on product type, verify:

-

Electrical safety certifications

-

Material safety standards

-

Environmental compliance

-

Consumer protection regulations

Compliance reduces legal and platform risks.

Step 9: Evaluate Long-Term Supplier Stability

You want a supplier who can support long-term growth.

Assess Production Capacity

Ask about:

-

Manufacturing scale

-

Inventory stability

-

Customization capability

-

Peak season readiness

Supply shortages can disrupt your business.

Check Business Consistency

Look for:

-

Stable pricing

-

Reliable restocking

-

Consistent quality batches

Consistency ensures predictable operations.

Step 10: Conduct Small-Scale Market Testing

Before scaling, test demand and customer satisfaction.

Launch a Trial Campaign

Sell limited quantities to evaluate:

-

Customer reactions

-

Return rates

-

Review feedback

-

Support requests

Analyze Performance Metrics

Track:

-

Conversion rate

-

Refund percentage

-

Customer satisfaction

-

Product complaints

Use data to decide whether to scale.

Step 11: Monitor Product Performance Continuously

Verification doesn’t stop after launch.

Track Customer Feedback

Regularly review:

-

Product reviews

-

Customer emails

-

Support tickets

-

Return reasons

Maintain Supplier Communication

Stay in touch with suppliers to:

-

Address quality issues

-

Improve packaging

-

Upgrade materials

-

Adjust specifications

Continuous monitoring ensures long-term success.

Step 12: Use Data Tools for Ongoing Quality Insights

Modern sellers combine manual verification with data analytics.

Monitor Market Trends

Track:

-

Sales trends

-

Demand fluctuations

-

Competitor performance

-

Price changes

Analyze Competitor Stores

Observe:

-

Customer reviews

-

Product updates

-

Complaint patterns

-

Quality improvements

This provides valuable industry insights.

Common Mistakes to Avoid

Choosing the Cheapest Supplier

Low price often means compromised quality.

Skipping Sample Testing

Relying on photos or descriptions is risky.

Ignoring Negative Reviews

Small issues can become major problems.

Scaling Too Quickly

Test before investing heavily in advertising.

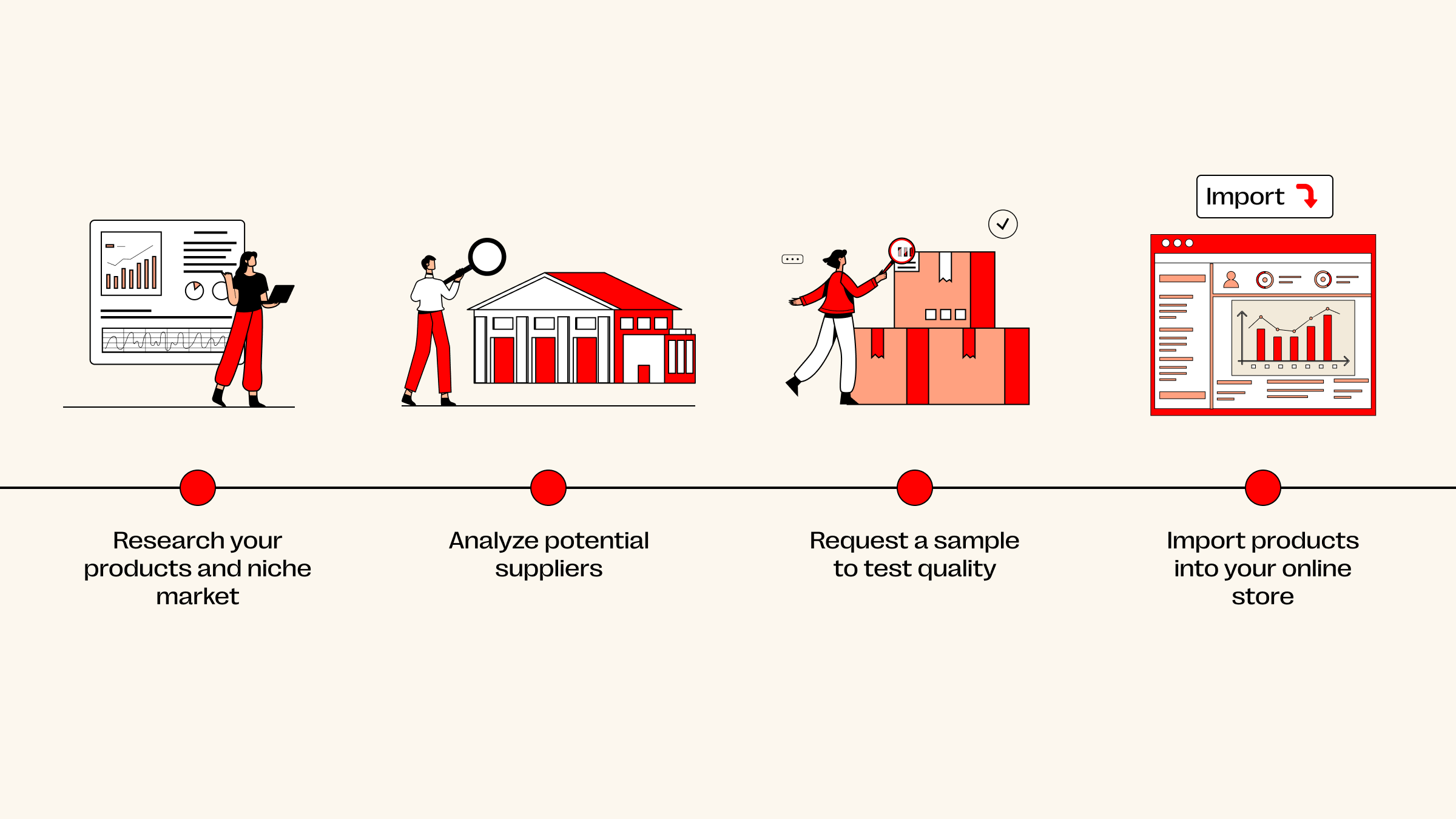

Building a Reliable Product Selection Workflow

Successful dropshipping businesses follow a structured process:

-

Identify trending products using research tools.

-

Validate supplier credibility.

-

Order and test samples.

-

Compare suppliers.

-

Verify shipping and packaging.

-

Research market feedback.

-

Test customer response.

-

Monitor ongoing performance.

This workflow minimizes risk and maximizes profitability.

The Competitive Advantage of Quality Verification

Many beginners chase trends blindly. Professional sellers focus on reliability and customer satisfaction.

When you verify product quality thoroughly, you gain:

-

Higher customer trust

-

Lower refund rates

-

Better reviews

-

Stronger brand reputation

-

Sustainable profit growth

Quality verification is not extra work—it’s a strategic advantage.

Final Thoughts

Product research tools make discovering opportunities easier than ever, but true success in dropshipping depends on what happens after discovery. Verifying product quality through supplier evaluation, sample testing, material inspection, shipping analysis, and market validation ensures you sell products customers love.

Instead of asking, “Is this product trending?” experienced sellers ask, “Is this product reliable, consistent, and worth selling long term?”

By adopting a multi-dimensional verification strategy, you protect your business, build trust with customers, and create a foundation for sustainable e-commerce growth.

The most profitable dropshipping stores are not built on quick wins—they’re built on careful decisions, rigorous testing, and unwavering commitment to quality.

8 min read

8 min read